PARTS

Guardian Environmental Products draws on our depth of experience when assisting our customers with requested parts.

Our staff provides one-on-one customer consultation on each parts request. Experienced engineers are available to provide technical resources to review wear, compatibility, chemical effects, and loading to offer the best solutions. We assist in properly identifying equipment previously supplied by other manufacturers, cross-referencing part numbers and materials to provide the appropriate guaranteed replacement. We often offer upgrades in material or selection while also maintaining a low cost to the customer. For any part or system inquiry please check out our Contact Us page to send a request.

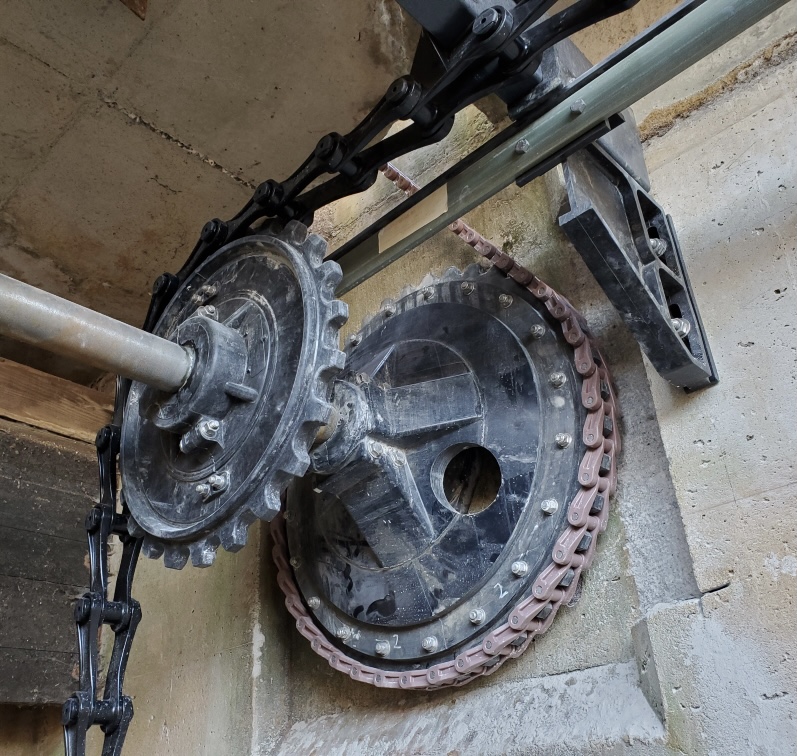

Chains

Guardian provides a wide variety of chain options depending on each individual application. We evaluate the specific loads and abrasion conditions to recommend the best selection for the application. We evaluate existing equipment and guarantee compatibility. Some of our chain specialties include:

Cast Iron

Manufactured to ANSI standards

4,400 lb working load

50,000lb ultimate strength

Weight: 5.2 lbs/ft

Cast Iron

Manufactured to ANSI standards

4,400 lb working load

50,000lb ultimate strength

Weight: 5.2 lbs/ft

Plastic

Highly abrasion resistant molded acetal with a 3,100 ln working load

Curved chain saver sidebars

F226 & F228 attachment links

Easy to assemble and disassemble with positive locking pin

Stainless Steel

403 Stainless steel

29,000 lb Ultimate strength

Curved chain saver sidebars

Weight: 3.7 lbs/ft

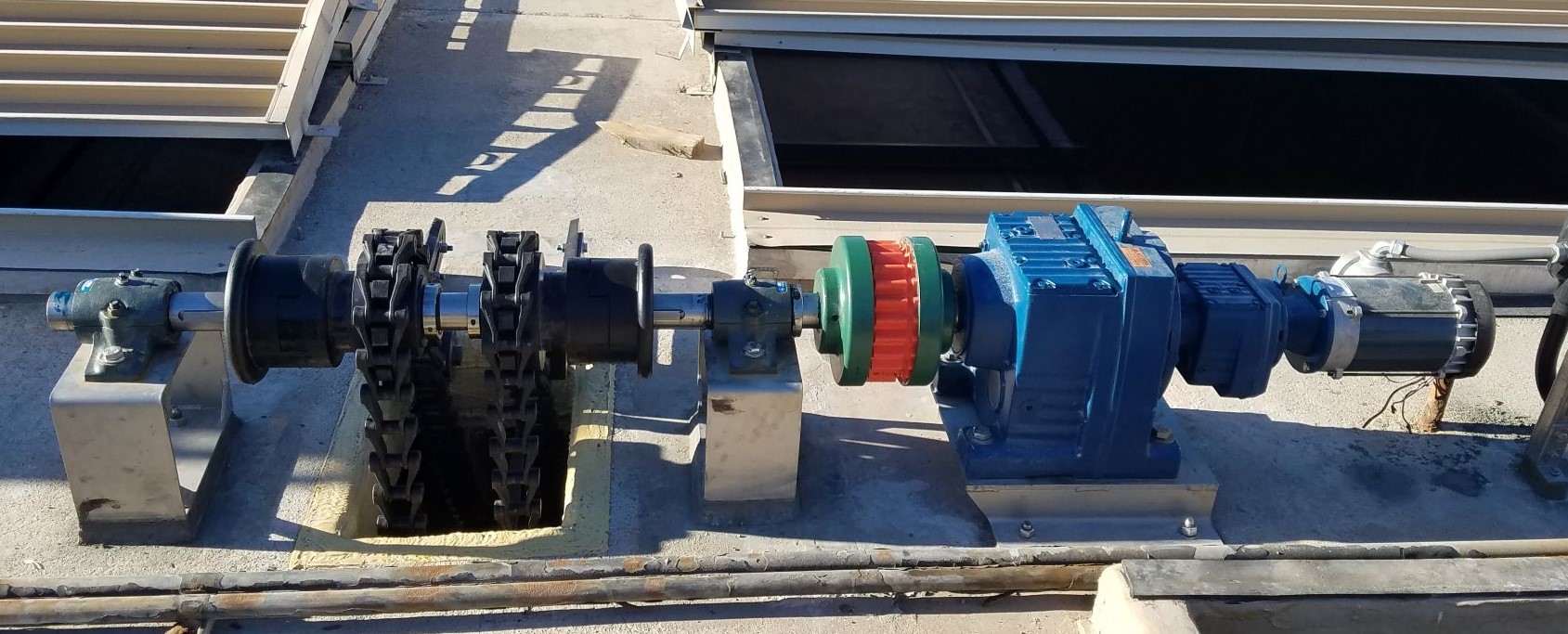

Drives & Components

Guardian provides compact and efficient drive systems to meet all configurations and conditions. Our innovative Collector Failure Protect (CFP™) and Biologically Optimized Sludge Removal System (BOSS™) have led the industry to newly discovered and unmatched levels of reliability and performance. With multiple available mechanical overload drive sprockets and material options for chains and sprockets, Guardian can meet any operating conditions and customer preference.

Click to download PDF:

Drive Sprocket/Shear Pin Hub Specs

Flights

Guardian’s broad range of flight options results in the best available technology for each customer’s application needs. All flights are cut to length, drilled and notched exactly to the customer’s needs or specifications. All flights match 6 or 8-inch standard attachment profiles, however, custom attachments can also be provided for existing installations.

Pivoting Stainless Steel Flight

High Strength Flight

Ultra High Strength Flight

Sprockets

Guardian Environmental offers the widest range of available sprockets in the industry. We custom apply our designs to suit every application.

- Polyurethane sprocket is the industry-leading, highest strength available, in a fully molded polyurethane sprocket with integrated chain saver rim

- Cast nylon sprockets are very strong and popular option also including a chain saver rim

- Cast iron with UHMW or nylon teeth segments are available for those customers looking for high strength hub with the lowest friction replaceable teeth segments

- Rigid set screwed, keyed, or free-wheeling with sleave bearing are available options and can be applied for economic retrofit and high performance

- Dished driven sprockets with a variety of custom or standard dished offsets in polyurethane or cast nylon

- Other custom options also available.

Guardian Environmental’s experience can identify most other manufacturer’s sprockets and replace and often upgrade their equipment.

Contact Guardian with your information and let us cross-match your product and offer you upgrade or cost savings options.

Guardian Environmental’s experience can identify most other manufacturer’s sprockets and replace and often upgrade their equipment.

Contact Guardian with your information and let us cross-match your product and offer you upgrade or cost savings options.

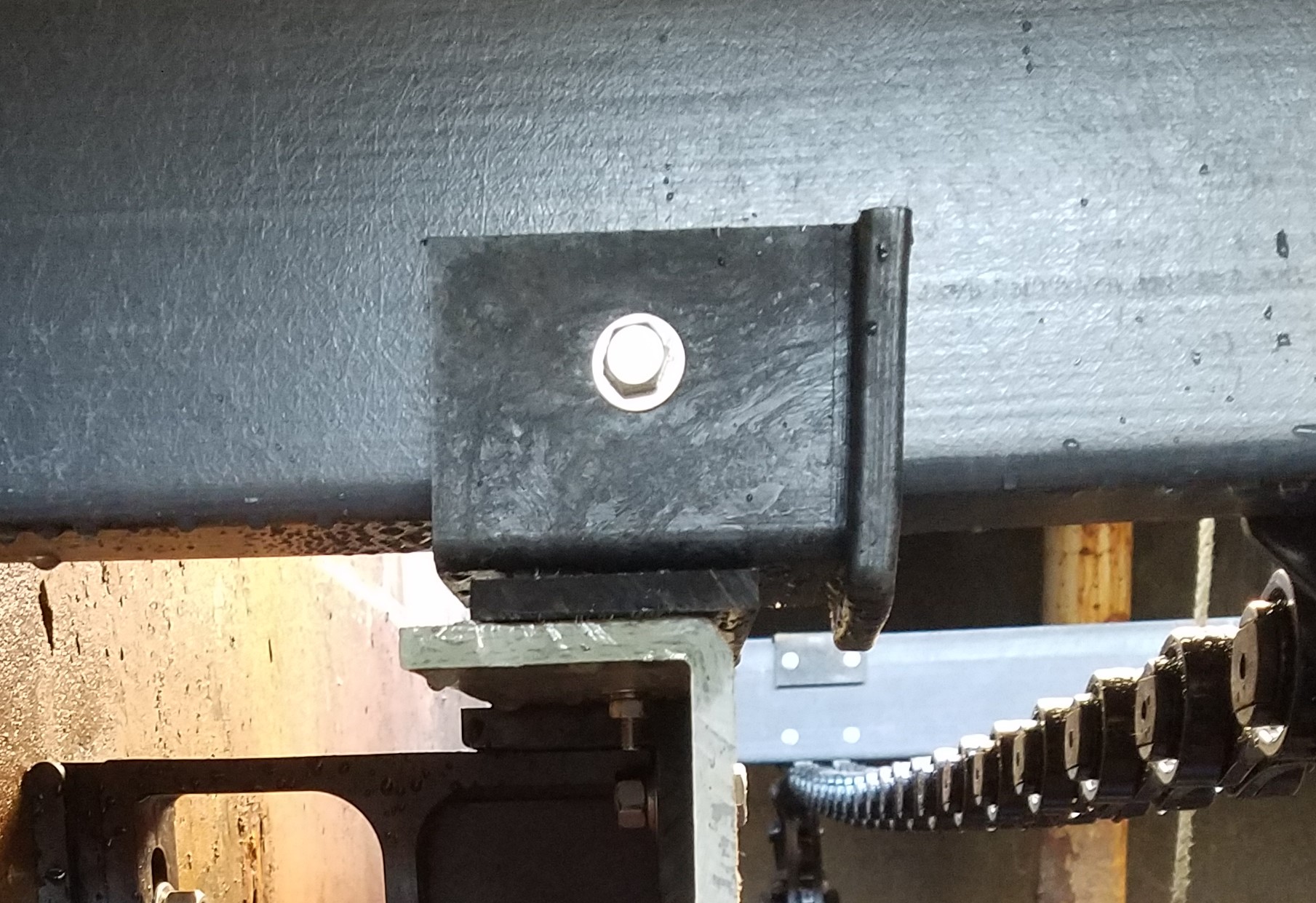

Wear Components

Wear Shoes

Wear shoes made of UHMW Polyethylene, Nylon, or Polyurethane are available.

Guardian will custom match wear shoes for any application and guaranty their compatibility.

Wear Strips

Wear strips are manufactured with UHMW polyethylene and designed to match any profile or width that is required.

Standard wear strip is 2-5/8″ wide x 10 ft long and includes mitered ends to ensure smooth flight transition.

Wear strips are secured with stainless steel hardware specially matched to the wear strip profile to eliminate and potential for binding of expansion or contraction due to temperature changes.

*Wear shoes and strips are guaranteed to be direct replacements of those previously provided by manufacturers like FMC, Envirex, Budd, Polychem or many others. Please identify your original supplier or dimensions when ordering.

Click to download PDF:

Bearings

Guardian Environmental offers options for customer consideration. Our preferred design includes rotating full width steel shafts in wall mount bearings. Our experience dating back to the 1960’s has shown this to be most reliable and most efficient in maintaining the best chain alignment.

We also offer many different design options to provide excellent performance and long-term reliability including:

- Static shafts with UHMW sleeve bearings

- Stub shafts with UHMW bearings

- Urethane wall bearings with UHMW sleeves to maximize surface area in an easily renewable bearing

- Cast iron housing with UHMW bearing allows for self-alignment, excellent performance and ease of installation.

Guardian Environmental also can match several major manufacturer’s design and bolt patterns to make upgrade and retrofit easy, economical, and reliable.

Polyurethane Bearing

UHMW Sleeve Bearing