PRODUCTS

Rectangular Clarifier Systems & Our TROLL™ Collector System

Guardian applies our experiences in application, engineering, and sales of chain and scraper clarifiers, to bring a truly integrated and customized solution to each of our customers’ wastewater treatment system needs. Our staff provides one-on-one customer consultation to ensure proper equipment is matched and provided, aiming to exceed each customer’s expectations.

- Our fully, custom designed TROLL™ Collector System is highly ranked among wastewater professionals in the industry

- We offer innovations compatible with any rectangular clarifier system, include the Collector Failure Prevention (CFP™) monitoring system and Biologically Optimized Sludge removal System (BOSS™)

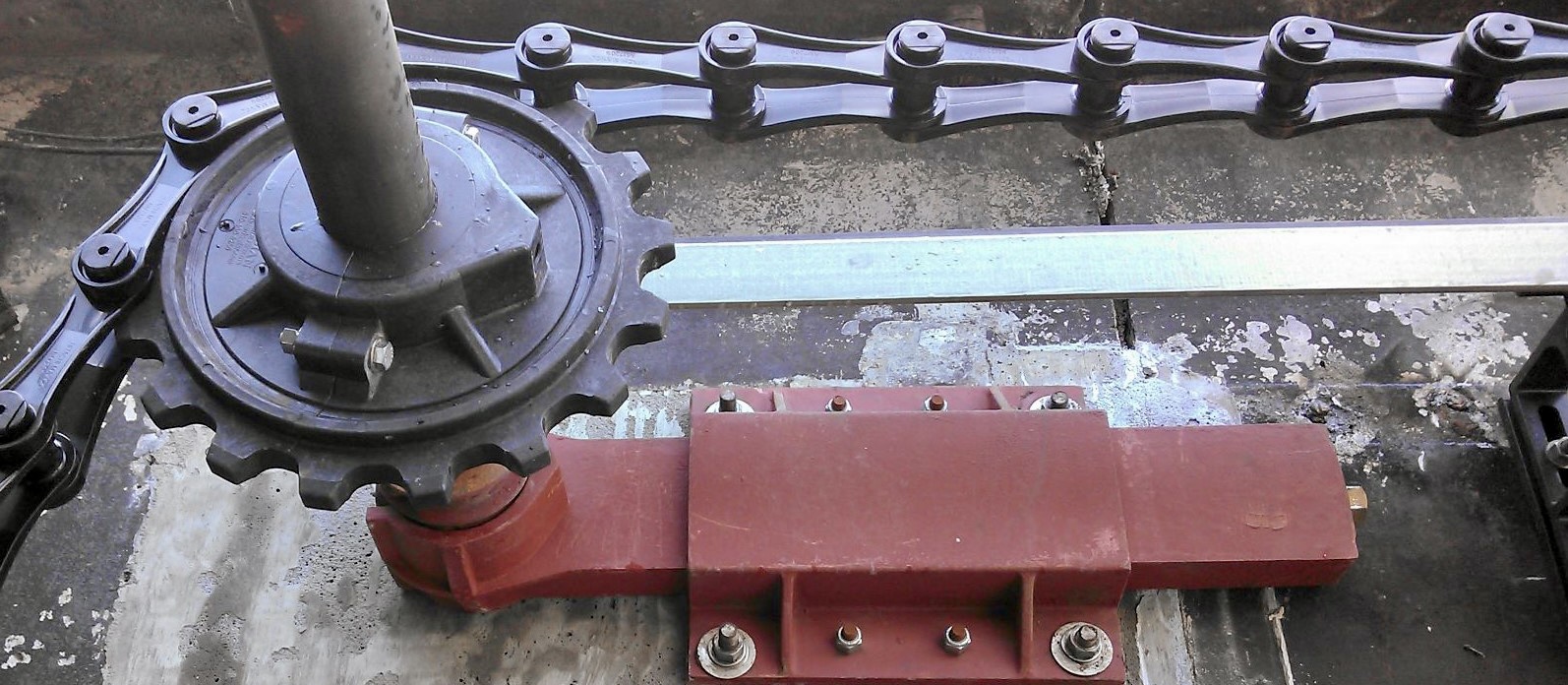

- We offer a variety of material options including high strength polymeric, nylon, UHMW polyethylene or cast iron body sprockets with non-metallic, stainless steel, welded steel, cast stainless steel, or cast iron chains. These combinations are engineered and selected for process considerations, sludge loads, abrasives, corrosive content, and temperature to provide the best long-term performance and operating costs with our Guardian Troll Collector Systems.

DAF Systems

Dissolved Air Floatation (DAF) systems are used for enhanced floatation or thickening. The DAF separator uses microscopic air to enhance the floatation of particles that would settle or rise slowly through gravity separation to enable smaller tankage. The Dissolved Air Floatation Thickener uses similar microscopic air technology to thicken high solids waste such as Waste Activated Sludge (WAS) and thickens the material prior to digestion or dewatering. This greatly reduces the digester volume or overall capacity.

DAF System scum collectors using Guardian Environmental Products chain and flight collection system, effectively removes high solids, floated material, and further dewaters up a dewatering beach before collection. Pivoting flight or all non-metallic with fiberglass flight designs are available. Bottom tank collection systems of chain and flight or screw collector designs effectively remove settled solids.

Refinery API Systems

Rectangular API collectors are used for separation of wastewater flowage using floatable petroleum products which float, and heavier sludges that sink. These systems require the experience of Guardian Environmental Products wastewater engineers in proper design configurations and material selections to ensure a reliable system. Most refinery API collectors are covered with either floating covers or structural covers with nitrogen gas blankets. Each adds a complexity and need for equipment reliability significantly different that typical municipal applications.

Guardian Environmental Products TrollTM – API system is custom designed to meet all treatment and environmental needs of present-day refineries:

- High temperature compatible non-metallic components

- Operation and monitoring system with our CFP system (Collector Failure Protection) for reliable operation in covered tank systems

- Hydrocarbon exposure material selection

- System design for varying temperature waste

- Enhanced separation and removal efficiency rates

Controls

Guardian Environmental Products design and control options are customized for every application and every user. Our systems range from local start/stop controls to sophisticated PLC controls that are able to monitor and control all aspects of the collector system as well as the overall performance of the complete clarifier system all through a touch screen display.

Our process experience combined with our rectangular clarifier design experience are unmatched in the industry. Our CFP (Collector Failure Protection) system and BOSS (Biological Optimized Sludge System) are exclusive designs that can be integrated to the plant SCADA system for the ultimate control and optimization. Our system designs include features such as:

- Flight position and motion monitoring

- Chain alignment

- Constant torque control

- Suspended solids overflow optimization

- Flow rate adjustment

- Sludge blanket monitoring and optimization

- Automated sludge and skimming withdrawal

Scum Pipes

Scum pipes are used to collect and discharge floated material to nearby scum for removal or digestion. We provide a variety of designs to fit every customer’s needs and system requirements. Material options include steel, stainless steel, and fiberglass. Systems can range from manually actuated lever control to rotate the scum pipe and withdraw float to handwheel actuated to automatically actuated with an electric actuator. Our shop fabrication can often provide the maximum corrosion protection, through the use of our stainless-steel design that is not affected by UV light or environmental erosion for the same cost as other supplier’s fiberglass or carbon steel designs.

- Stainless steel, carbon steel, and fiberglass designs

- Manual lever or handwheel actuated

- Automatic electric actuator designs

- Integrated into Guardian Environmental Products exclusive BOSS control system and plant SCADA

Fiberglass

Carbon Steel

Stainless Steel

Weirs & Troughs and In-tank baffles

Weirs and troughs

Guardian designs trough and weir configurations for proper end even flow distribution. Or troughs can be either stainless steel or fiberglass and include leveling and adjustable v-notch or flat weirs.

In-Tank Baffles

In-tank baffles are used for influent flow distribution to diffuse influent energy and disperse flow to plug flow.

- Mid-tank are often used to divert flow and enhance settling

- Scum baffles are used to retain floated scum prior to the effluent troughs and concentrate for removal by the scum pipes.

- Fiberglass or Stainless Steel

Looking for information on parts? Check our parts page.

Guardian Environmental Products, Inc.

P.O. Box 3954, Charleston, WV 25339

610-430-6200 • info@guardwater.com